C-Loop Biorefineries

Our Biorefineries deliver sustainable solutions for waste management and renewable energy.

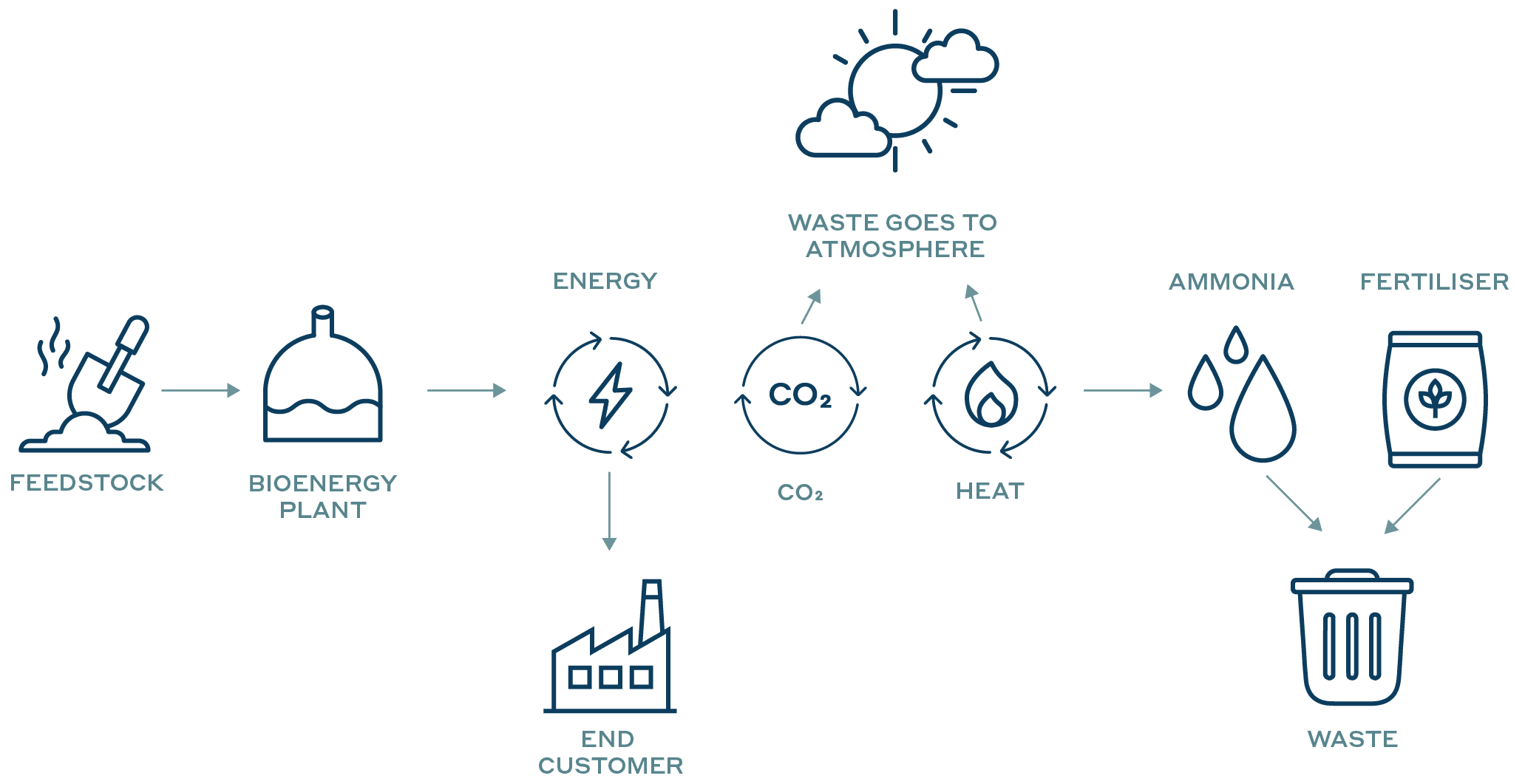

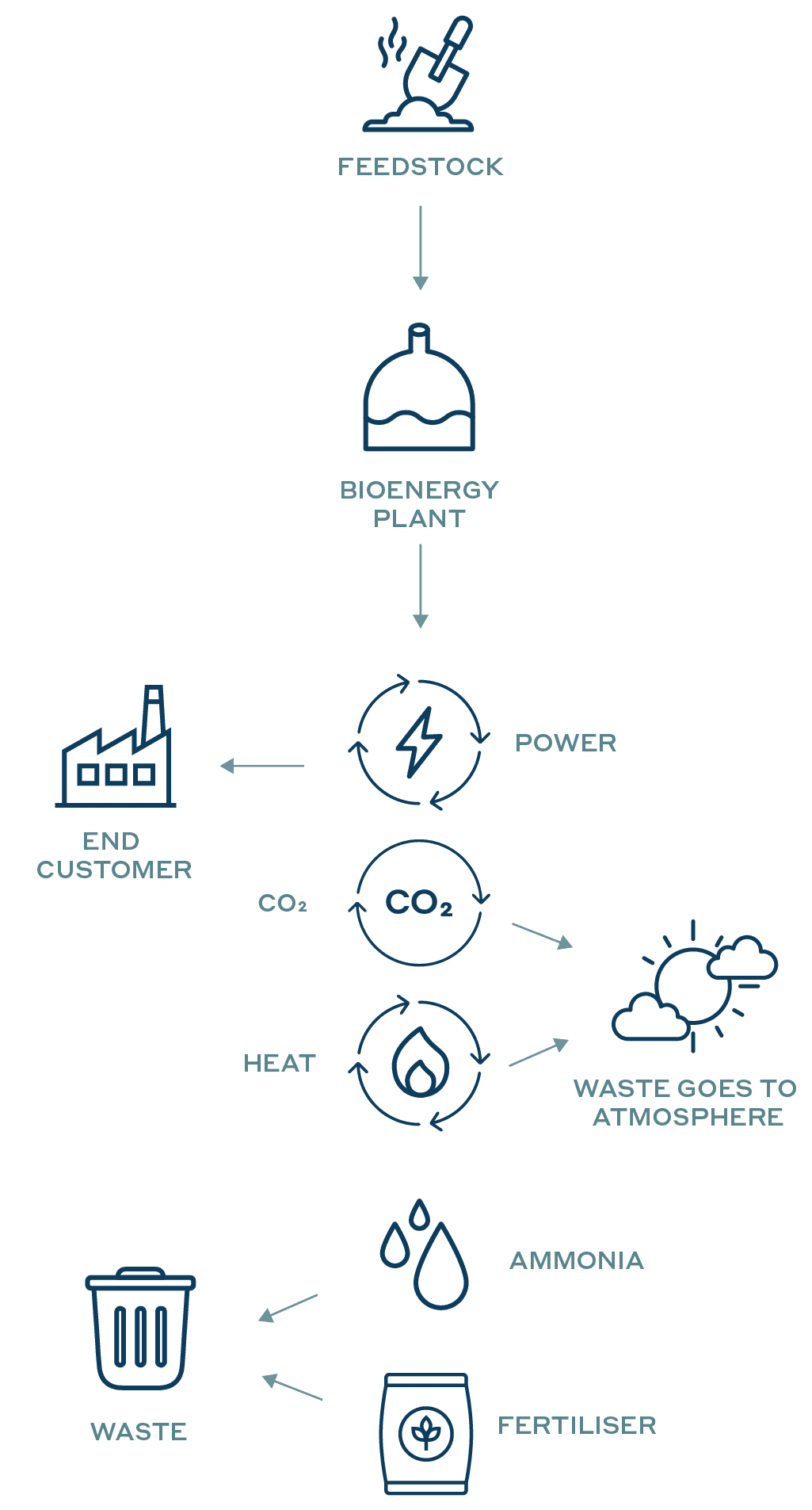

Linear Bioenergy

Most Bioenergy Plants operate a linear model focussed on energy generation as a way of managing waste. Whilst good in theory, this model creates additional challenges to manage and doesn't enable the full potential of the bioenergy process to be realised.

This approach leads to sustainability outcomes which are commercially reliant upon government schemes and limited sources of revenue to remain viable.

When looking at bioenergy this narrowly, we miss the bigger picture. Valuable by-products from the process - like biogenic CO₂, renewable heat, and nutrient-rich digestate have value to markets globally!

In other words, the process outputs are underutilised.

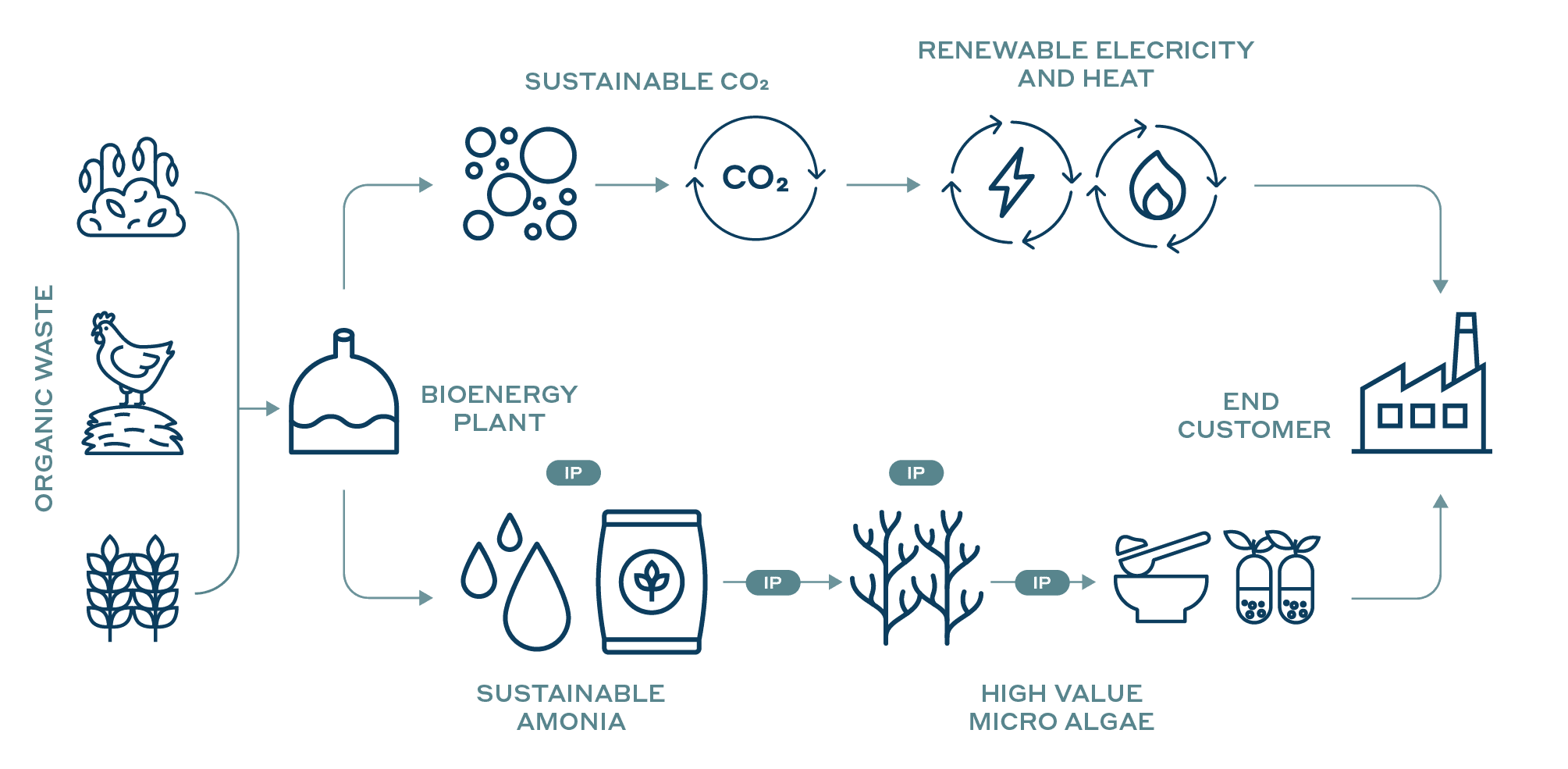

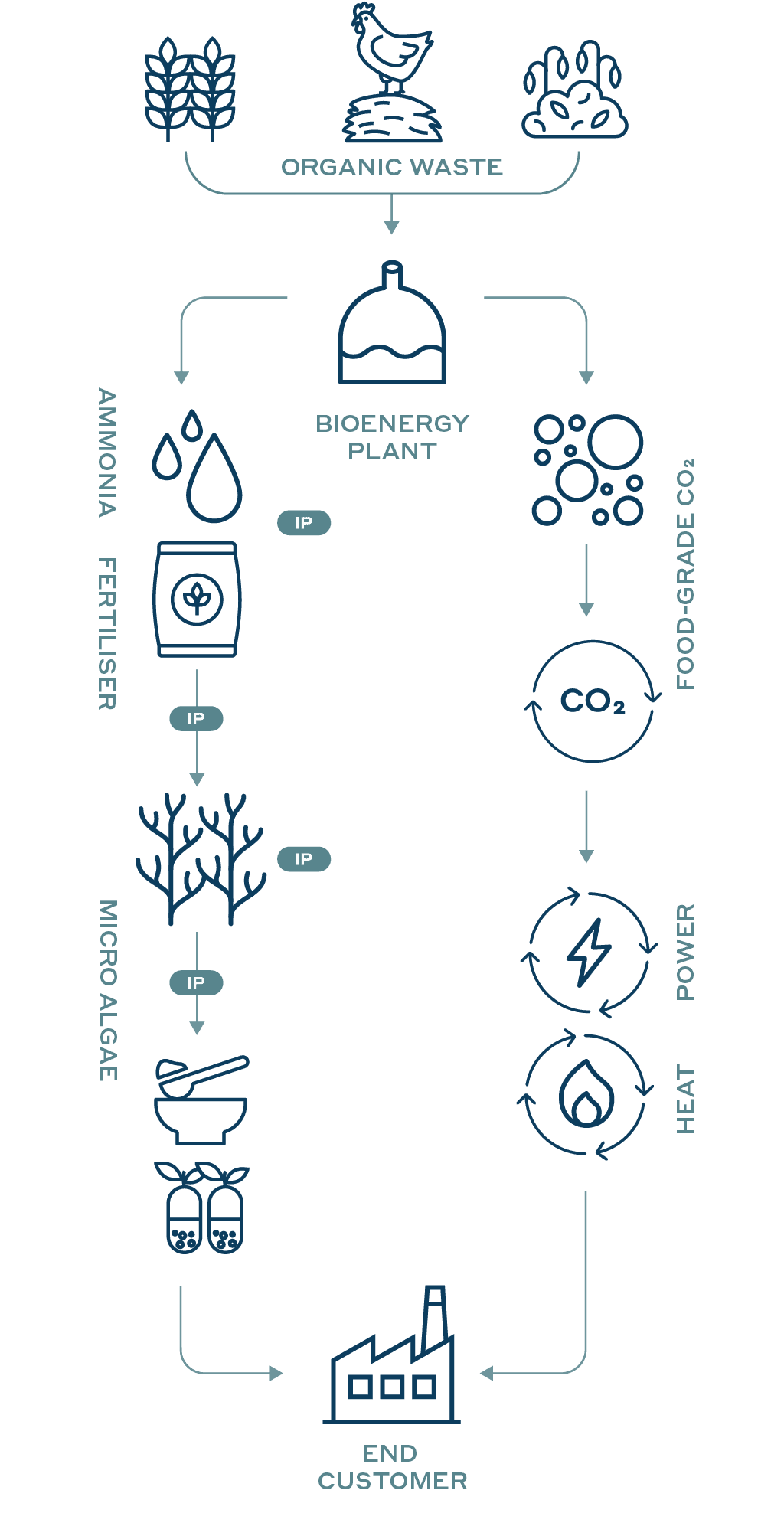

C-Loop's Biorefineries

C-Loop's Biorefineries recognise this value and fully valorises each output, creating circular outcomes that benefit multiple stakeholders, without the need of charging a green premium along the way.

Organic waste from our feedstock supply partners in the agriculture sector is continuously fermented through anaerobic digestion at the 'bioenergy' section of the biorefinery. This process then creates two outputs:

Biogas containing methane

And digestate — a nutrient dense mix in a semi-solid state

The biogas is separated into two parts, food grade CO₂, sustainably produced for the food and beverage markets, and biomethane, which when combusted produces baseload electricity and a renewable heat source which can be used by energy users who depend upon heat and electricity from co-generation. Excess renewable electricity from co-generation is exported to local electricity grid supporting the energy networks with renewable energy when the grid needs it most.

Digestate is further enhanced, the liquids and residual heat are introduced to raceway ponds to cultivate micro algae under C-Loop's biorefinery process, with the remaining solids from the digestate supporting the fertiliser sector due to its nutrient rich makeup.

The cultivation of micro algae through C-Loop's patented biorefinery is unique. Flue gas from co-generation contains CO₂, an essential part of the cultivation process. It provides an ideal carbon source for photosynthesis whilst micro algae flourish in the presence of ammoniacal nitrogen (present in the digestate) and yield high levels of protein (>60%). The final high-value product is micro algae such as Spirulina and Chlorella with high protein content with a net zero footprint grown in a bio secure environment unseen anywhere else globally.

The beauty of C-Loop's biorefinery enabling so many outcomes that meet the needs of multiple markets, ensures no green premium is charged along the way, meaning consumers don't pay for sustainable outcomes.

Explore our projects

See how we're turning organic waste into renewable energy and high-value products across Australia.

View projects